10 Jun Inventory Management for Kitchen Cabinet Components

Inventory Management for Kitchen Cabinet Components

In kitchen cabinet manufacturing and sales, inventory management is a critical driver of business efficiency and customer satisfaction. When done well, it leads to smoother workflows, quicker installations, and repeat customers. When mismanaged, it results in delays, frustrated clients, and lost revenue. Whether you’re a cabinet dealer, distributor, or manufacturer, optimizing your inventory processes is essential to staying competitive.

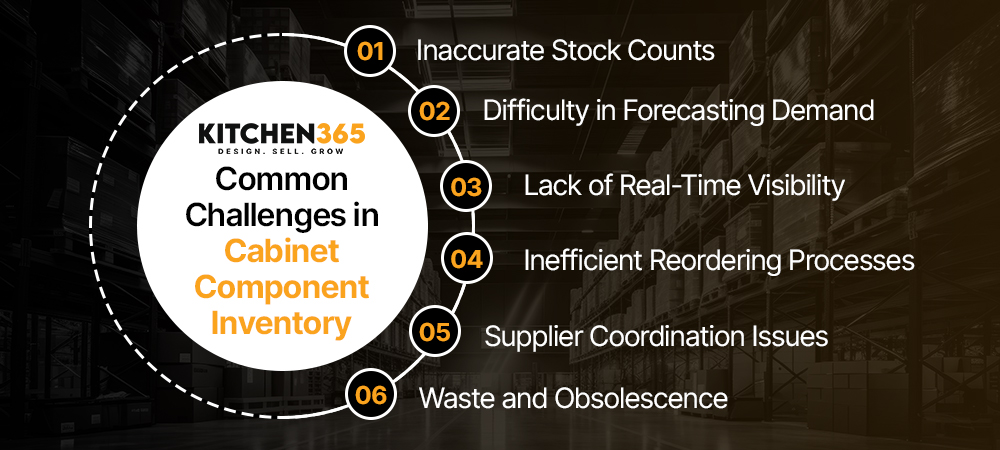

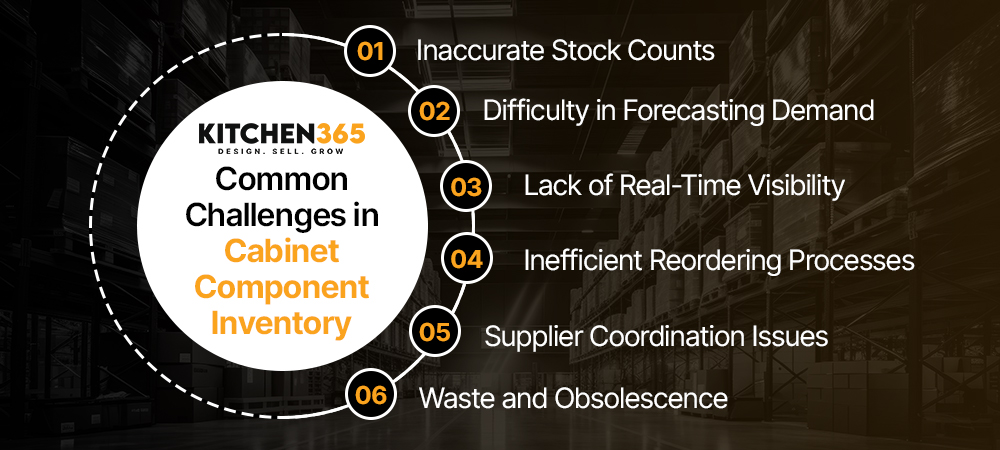

Common Challenges in Cabinet Component Inventory

Managing a diverse inventory of kitchen cabinet components presents several unique challenges. Without the proper systems and tools in place, businesses often find themselves struggling with the following:

-

Inaccurate Stock Counts: Manual tracking or outdated spreadsheets often result in discrepancies between recorded and actual inventory levels. Over 45% of businesses faced inventory shortages in 2023 because of global supply chain disruptions. This mismatch causes unexpected shortages or costly overstock situations, both of which disrupt project timelines.

-

Difficulty in Forecasting Demand: Customer preferences shift rapidly, and seasonal trends can significantly impact sales. Without reliable forecasting tools, companies may either over-purchase or understock and lose sales opportunities.

-

Lack of Real-Time Visibility: For businesses operating multiple warehouses, showrooms, or fulfillment centers, real-time visibility is crucial. Many organizations lack the necessary systems to monitor inventory across all locations, resulting in inefficient transfers, delayed shipments, and missed deadlines. Over 60% of manufacturers struggle with inaccurate inventory data, leading to excess stock or stockouts.

-

Inefficient Reordering Processes: When inventory systems don’t trigger timely reorders, replenishment is often reactive rather than proactive. Delays in placing orders can result in project hold-ups and strained supplier relationships.

-

Supplier Coordination Issues: A communication breakdown can result in delivery errors, misaligned lead times, and a lack of transparency.

-

Waste and Obsolescence: Overestimating demand or mismanaging inventory turnover can lead to storing obsolete components. Unused materials waste valuable space and often force businesses to write them off, directly impacting the bottom line.

Strategies to Avoid Stockouts and Delays

To overcome these challenges, businesses must implement a strategic approach to inventory management. The key is to shift from reactive to proactive processes. Leverage technology and data to stay ahead of demand and streamline supply chain operations.

1. Demand Forecasting -

Accurate forecasting is at the heart of effective inventory management. By analyzing historical sales data, customer buying patterns, and seasonal trends, businesses can more accurately anticipate demand for specific cabinet components.

More advanced forecasting involves using AI-driven analytics and considering external factors, like market trends. Companies using AI and machine learning report a 35–50% improvement in forecast accuracy. This predictive capability helps optimize order quantities, reducing the risk of both stockouts and excessive inventory.

2. Real-Time Inventory Tracking -

Modern inventory systems provide real-time visibility into stock levels, movements, and locations. This allows you to make data-driven decisions with confidence. Technologies such as integrated ERP systems automatically update inventory counts as staff receive, move, or dispatch components.

Real-time tracking prevents shortages, reduces manual errors, and improves warehouse efficiency. Researchers have shown that optimized inventory management practices improve order fulfillment rates by 30%.

3. Supplier Coordination -

Streamlining supplier relationships through integrated systems enhances order accuracy and on-time delivery. Automated purchasing workflows and shared data portals allow both parties to plan. This reduces lead times and avoids last-minute surprises.

Collaborating with suppliers on shared inventory visibility also helps maintain stock. Close collaboration with suppliers can reduce lead time variability by 20–35%. This is especially true for high-demand or long-lead-time items.

4. Inventory Replenishment Automation -

Automated reordering ensures that your inventory levels remain consistent, removing the need for constant manual oversight. By reordering based on lead times, stock thresholds, and forecasted demand, businesses can avoid running out of key components. Automation also reduces the burden on staff and minimizes human error.

How Kitchen365 Helps Streamline Inventory

This is where Kitchen365 becomes a game-changer. Kitchen365 offers a comprehensive suite of inventory management tools that directly address the pain points mentioned above. Here’s how Kitchen365 enhances your inventory management process:

-

Centralized Database: Access a unified platform where all inventory data lives. Kitchen365 tracks every item, whether hinges, drawer fronts, or complete cabinet sets, in one place, eliminating duplication and discrepancies.

-

Advanced Demand Forecasting Modules: Use historical sales data and industry trends to generate accurate demand forecasts. Kitchen365’s forecasting tools help you purchase smarter, reduce carrying costs, and minimize guesswork.

-

Real-Time Inventory Tracking and Alerts: Monitor inventory movement in real-time. The system automatically updates stock levels as it receives, transfers, or sells items. Set alerts to notify you when inventory drops below critical thresholds so you can act before it’s too late.

-

Automated Reordering: Create automatic reorder rules based on product performance and usage rates to optimize inventory levels. The system triggers reordering the moment inventory falls below your predefined minimum levels. This ensures top-selling or essential components stay in stock.

-

Integrated Supplier Management: Manage vendor relationships with ease. Kitchen365 enables you to generate and send purchase orders, track order statuses, and review supplier performance. This is all possible from a single, intuitive dashboard. This helps you avoid miscommunication and delays.

-

Reporting and Analytics: Use powerful reports to uncover trends, identify slow-moving stock, and improve warehouse organization. These insights can help you eliminate waste, allocate resources more efficiently, and fine-tune your supply strategy.

-

Multi-Location Management: Whether you operate multiple warehouses, showrooms, or distribution hubs, Kitchen365 enables seamless inventory management across all locations. You’ll get a comprehensive view of stock availability and movement, regardless of its location.

The Impact of Strategic Inventory Management

Kitchen365 is about transforming your business into a more agile, responsive, and profitable entity. With an inventory management system in place, you can focus on strategic growth, innovation, and customer satisfaction. Implementing real-time inventory management systems can lead to a 20% increase in customer satisfaction. The future of kitchen cabinet manufacturing and sales lies in smart, integrated solutions.

Final Thoughts

In the kitchen cabinet industry, your ability to manage inventory efficiently can be a defining factor in your success. Every delay or stockout not only incurs costs but can also erode customer trust.

By investing in intelligent inventory solutions like Kitchen365, businesses can eliminate inefficiencies, improve supplier coordination, and gain real-time insights that drive better decisions. You’ll avoid common pitfalls such as overstock, obsolescence, and missed deadlines while delivering better service to your clients.

Sorry, the comment form is closed at this time.